to airframe rivets,

our solutions redefine maintenance

through remanufacturing

back online sooner,

reducing downtime

Innovative systems for

seized fastener removal

Powered by electro-discharge machining (EDM) technology, our innovative FastEDR and ARTES systems safely and efficiently remove seized fasteners without the use of heat, force, or chemicals.

FastEDR is a portable tool that accelerates aerospace maintenance processes by enabling rapid disassembly, while virtually eliminating the risk of component damage.

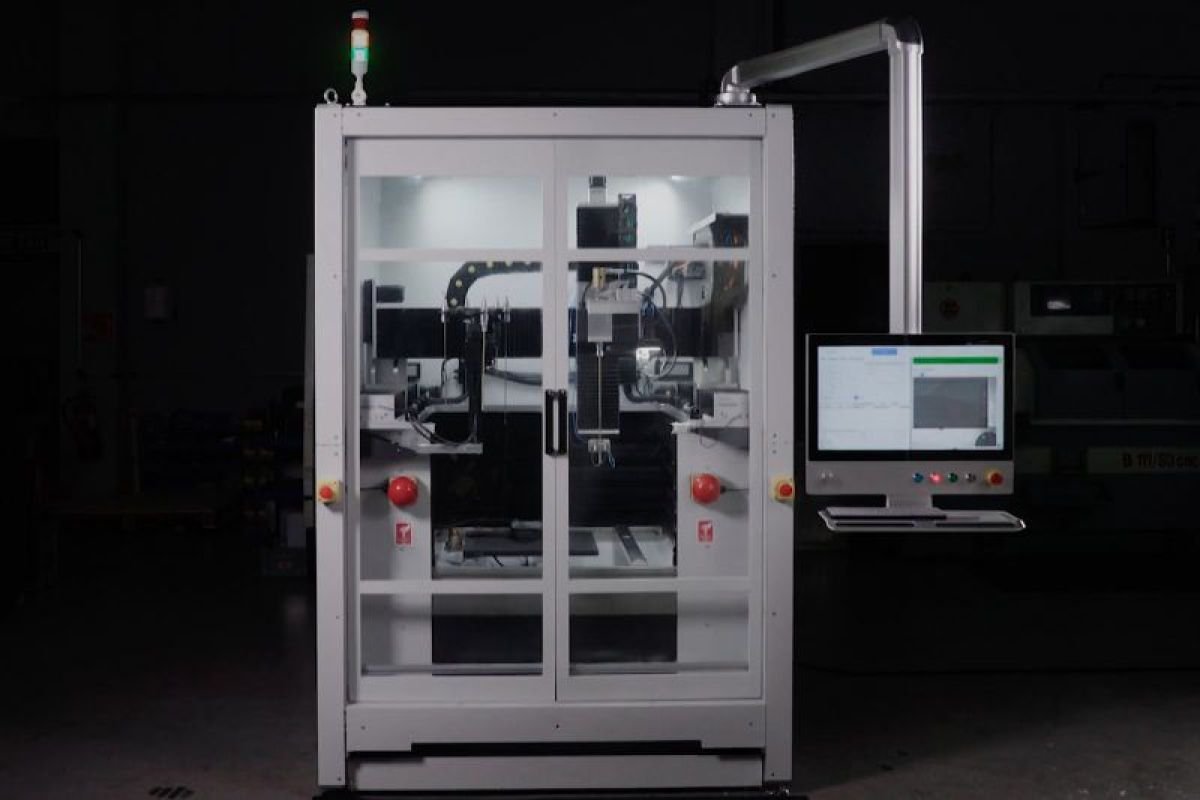

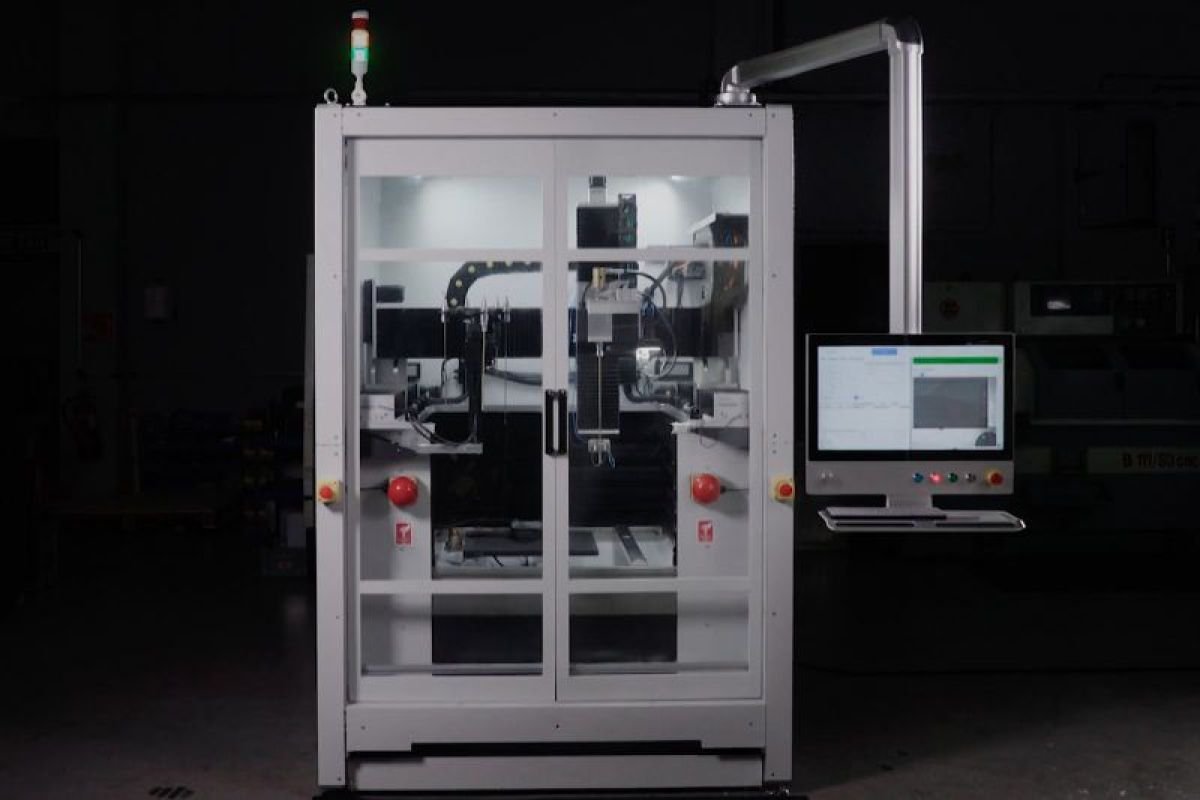

ARTES is a high throughput, large-format EDM machine that simplifies remanufacturing by removing seized fasteners while unattended. It stands for ‘Automated Remanufacturing Towards Environmental Sustainability’ and transforms scrap metal into valuable components.

Our solutions increase business productivity and efficiency, providing certainty of scheduling through repeatable, measurable processes. This minimises downtime and consequent costs. They don’t require specialist expertise to operate, and have been designed to be operator-friendly and intuitive.

See how FastEDR works

Our portable fastener removal tool helps boost the speed of aerospace maintenance, by enabling rapid disassembly while virtually eliminating risk of component damage.

The benefits

Increased operator safety

Increased operator safety

Unpredictable maintenance operations carry significant risk to the workforce, procedures which minimise this take time and can be costly to implement. FastEDR technology provides a safer solution, where high forces, significant heat and toxic chemicals can be avoided.

Cut process times by up to 80%

Cut process times by up to 80%

Removal of seized components results in significant downtime across sectors. Scintam’s purpose built technology can reduce this downtime drastically, getting systems back online sooner. Compared to traditional methods FastEDR reduces repair process times by up to 80%.

Certainty during scheduling

Certainty during scheduling

Whether the application is one where seized components are inevitable, or if they are an occasional issue, uncertainty over whether they can be causes problems. By having FastEDR on hand, this uncertainty can be eliminated, making scheduling more accurate and reliable.

Reduced damage rates

Reduced damage rates

Scrap is reduced by ensuring the correct tool is always used, located and confirmation data is received by the operator. Our specialist tools are purpose built for the job, meaning problems such as misalignment and slippage only occur in the most extreme cases.

Predictable & repeatable

Predictable & repeatable

FastEDR uses physical engineering controls to ensure that the tools function correctly and consistently. Further closed loop software controls and data storage mean that quality is assured and can be audited at the push of a button. Our tools fit into your processes.

Portable and adaptable

Portable and adaptable

Adaptability is at the core of our tools, they can be easily moved to where they are needed, reconfigured to each scenario, and used with high levels of operator assurance. This makes our tools indispensable for both planned and unplanned maintenance operations.

Our sectors

We work across many industry sectors providing multi-purpose tools for a range of applications.

We design custom solutions in-house for particularly challenging applications.

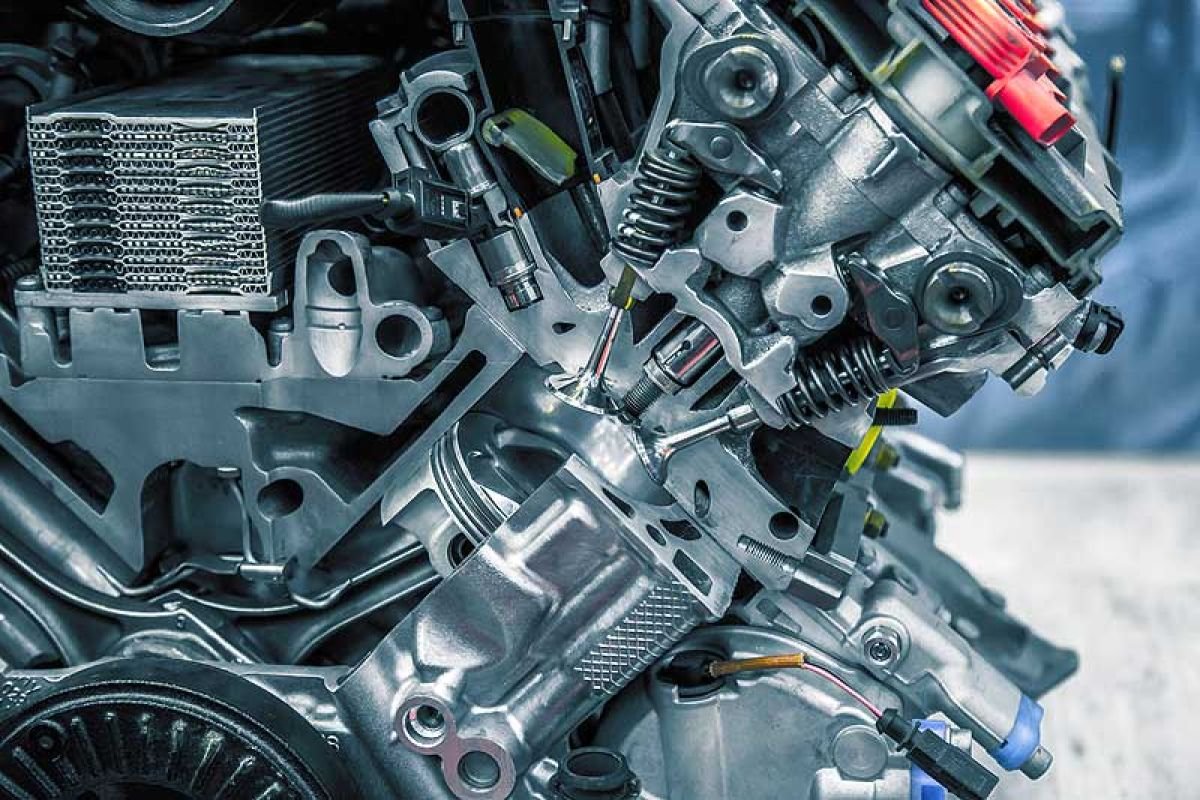

Machinery

Eliminate delays in asset maintenance. Our flexible tooling adapts to the varied fastener types seen in industrial machines.

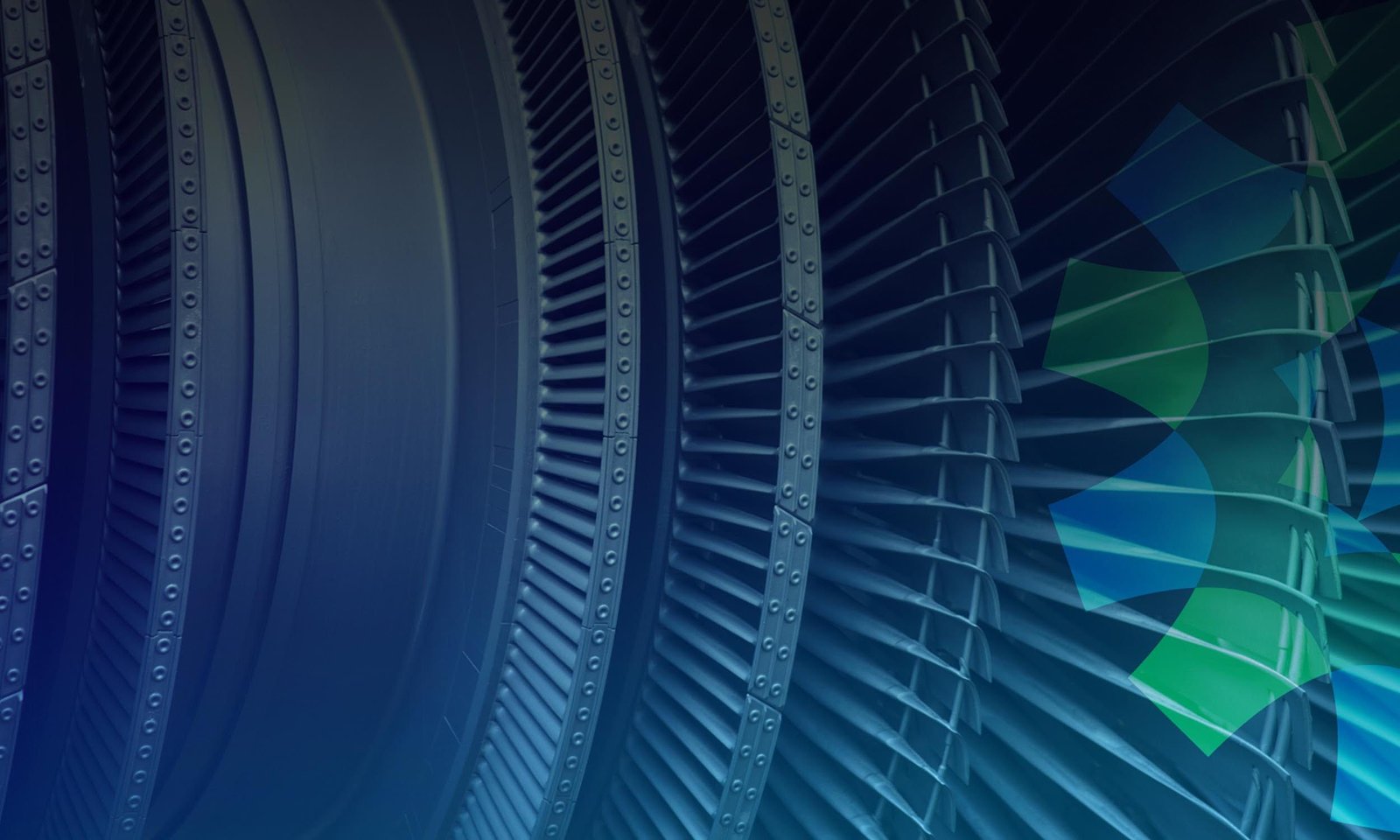

Aerospace

From gas turbine bolts to airframe rivets, our solutions redefine speed and damage rates during MRO operations.

Industrial

Planned or unplanned, maintenance means downtime. Get systems back online sooner by eliminating the risk of seized fasteners.

Nuclear Power

Exotic alloys, hazardous environments, robotic integration – we can handle them all. We will work with you to deliver the solution you need.

Remanufacturing

Our solutions can unlock the commercial viability of remanufacturing with high-throughput and low unit cost processing of used parts.

Renewable Energy

Working at height requires safe, reliable tooling. Our solution delivers fastener removal with no mechanical force or heat input.

Remanufacturing (2)

Our solutions can unlock the commercial viability of remanufacturing with high-throughput and low unit cost processing of used parts.

ARTES

Our solutions can unlock the commercial viability of remanufacturing with high-throughput and low unit cost processing of used parts.

FastEDR

From gas turbine bolts to airframe rivets, our solutions redefine speed and damage rates during MRO operations.

Let’s work together

We are actively looking for development partners, so if you are intersted in our products and services don't hesitate to get in touch with one of our team.

We reply to all communications promptly.

Backed by